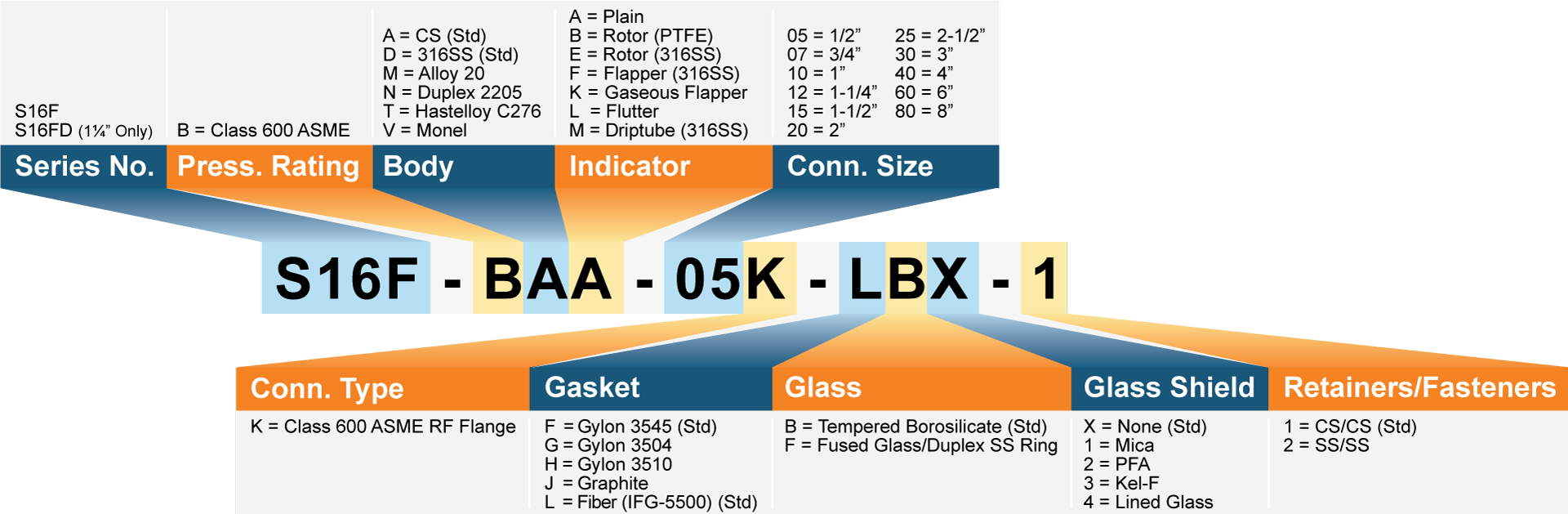

SERIES S16F

DOUBLE WINDOW SIGHT FLOW INDICATOR - CLASS 600 ASME FLANGED

(Was Model 210SH, 250SH)

Standard Features:

- Plain – No indicator for unobstructed view of media flowing in any direction

- Rotator – Paddlewheel indicator used for clear media to enhance flow indication in any direction

- Flapper – Side flapper to indicate horizontal flows in one direction for fast moving liquids

- Drip Tube – For vertical downward flows at low flowrates

Connection Sizes:

- 1/2″ to 8″ 600Lb ASME Flange

Options:

- Over 500°F Ratings

- Gylon®3504/3510, Graphite, and Fiber IFG-5500 Gaskets

- Gaseous Indicators

- Exotic Body Materials (See Matrix)

- Quartz and Fused Glass

- SS Glass Retainers & Fasteners (See Matrix)

- Glass Shields for Steam and Caustic Applications (See Matrix)

- C of C, MTR, NACE Certifications when requested at time of quotation

- Offshore Coating

- Custom Painting

- Lined Bodies (See Matrix)

Application Notes:

- Saturated Steam Service: Upgraded gaskets and mica shields are recommended for saturated steam service. All ratings stated on our website and in our literature are non-steam ratings unless specified otherwise. Always contact our sales office for saturated steam ratings when needed.

- Gaseous Service: Not designed for lightweight gases

- Corrosion: Before ordering, verify all materials of our sight flow indicators are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. Ernst Instruments does not make chemical compatibility recommendations. Compatibility is the responsibility of the user.

Replacement Parts:

- Please contact our Sales Department

Alternate Equipment:

- None (for 600LB only)