(Was Model 482, 487, 492, 497)

Benefits & Features

- Designed to be welded directly on the vessel wall.

- Use in up to 2000 PSIG.

- Transparent or Reflex Glass.

- Ideal for Applications with Viscous Liquids or with Liquids with Solids.

- Radius pad options are available. Please Inquire.

- Wetted Parts conform to ASME B31.3, AISI, and ASTM specifications

- Retainers/Covers are Shrouded to Protect the Glass Edges

- User must determine if the product is acceptable for ASME Sec. III

Reflex vs Transparent

- Reflex – The level of the media in the vessel appears black and the prismatic glass reflects silver where the liquid is not present. Light is only required in the front of the gauge.

- Transparent – For direct visual observation of the vessel’s liquid, level, quality, and color. Light is recommended from the back or inside the vessel.

| General Differences – Series H11B | Reflex | Transparent |

|---|---|---|

| Prismatic Glass that reflects back (requires a frontal light source) | Yes | No |

| Clear Glass to see through (requires a rear light source) | No | Yes |

| Clear Liquids | Recommended | Yes |

| Non-clear liquids | Yes | Recommened |

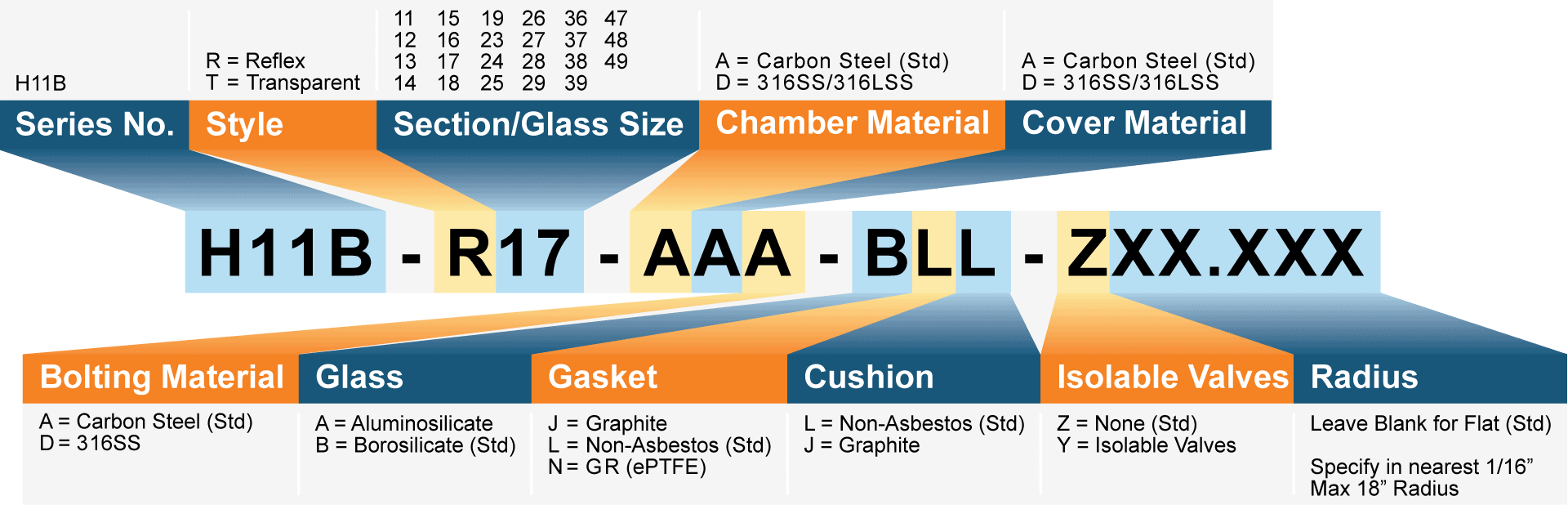

Options

- For Curved Radius Weld pads, Please Inquire

- Weld Spacers available to Prevent Warping while Welding

- Isolable Valves available to reduce process downtime for routine maintenance

- See Matrix for standard options

- Wetted NACE MR0175 & MR01033 compliance available

Application Notes:

- Saturated Steam Service: is not Recommended

- Potable Water: Carbon Steel wetted materials are not suitable for potable water, 316SS chambers are suitable

- Compatibility: Before ordering, verify all materials are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. Ernst Instruments does not make chemical compatibility recommendations. Compatibility is the responsibility of the user and/or specifying party.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov

Replacement Parts

- Please contact our Sales Dept. sales@ernstinstruments.com or call 888-943-5000