INDUSTRIAL DIGITAL FLOW METERS – ALUMINUM

SERIES GPI-G2 Industrial Grade Digital Meters - Aluminum

(Was Model 31904A)

Meter Type

Industrial Grade Digital Turbine Flow Meter, battery powered that displays rate of flow and totals.

How It Works

Magnetic pulses are picked up by a coil. The computer converts the pulses into a flow rate and totals.

Standard Features

- Rate of Flow, 2 Totals (1 Resettable Batch, 1 Cumulative)

- User Configurable to GPM, LPM or any Unit of Measure

- Factory Calibrated for 1.0 Specific Gravity

- Field Calibratable for fluids greater than 1.0 Specific Gravity

- Digital Display with 6 Digits Starting at 0.01 (floating decimal)

- Totals Maximum of 99,999,999

- Powered by (2) 1.5V AAA Alkaline Batteries (2-year life)

- Factory Calibration Certificate supplied with each meter

- Suitable for Fuel, Diesel, Petroleum Based Products or other suitable applications

- 1 Year Limited Warranty

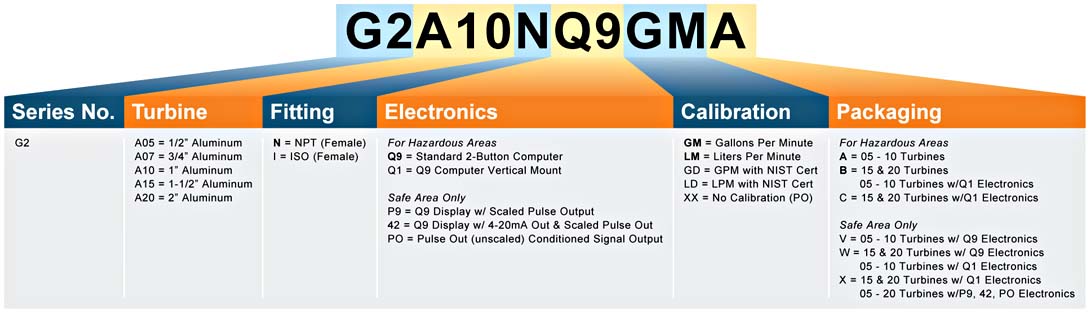

Options

- Field programmable for Gallons or Liters

- Quarts, Cubic Feet, Barrels, Cubic Cent., Ounces

- Rates per Minute, Hour or Day

- ISO Connections

- N.I.S.T. Flow Certificate

Replacement Parts

- See Series: GPI-P317

Optional Accessories

- 4-20mA Output Module

- FM Approved Remote Display Kit (increases meter rating to 250°F)

- Pulse Access – Dust Cover for Remote Kit (provides digital open collector [NPN] output signal)

- Conditioned Signal Output Module

- Pulse Access Module

- 90° Display Adapter Kit (for vertical installations)

Alternate Meters

Application Notes

- Saturated Steam Service: Not acceptable

- Potable Water: Not acceptable (See Series GPI- QSE)

- Vacuum Service: Not acceptable

- Gaseous Service: Not acceptable

- General Non-Suitable Services: Not recommended for water applications. Not suitable for medias with varying viscosities.

- Installation: Limit display’s exposure to sun.

- Corrosion: Before ordering, verify all materials of our flow meters are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. John C. Ernst Co. does not make chemical compatibility recommendations. Compatibility is the responsibility of the user and/or specifying party.