(Was Model 341) (Was Model 320/316) (Was Model 322) (Was Model 722) (Was Model 723)

Benefits & Features

- Provides direct visual observation of process in vessels or pipe

- Threads directly into female half coupling

- Fused Glass units suitable for vacuum service

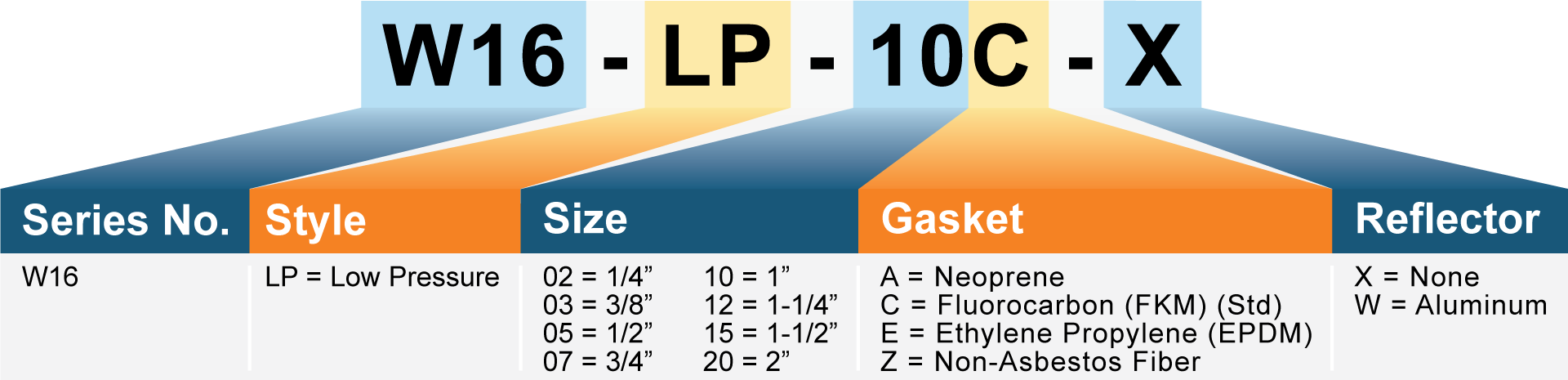

- Sizes 1/4” to 3”MNPT

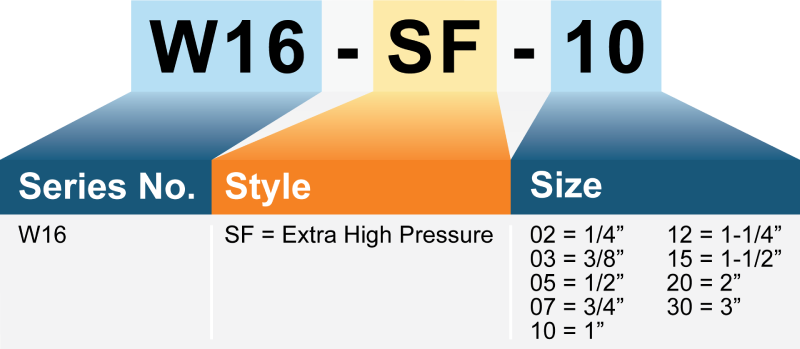

- Style SF has superior fused glass clarity

| Standard Specifications* | ||||||

|---|---|---|---|---|---|---|

| Wetted Materials | Non-Wetted Materials | |||||

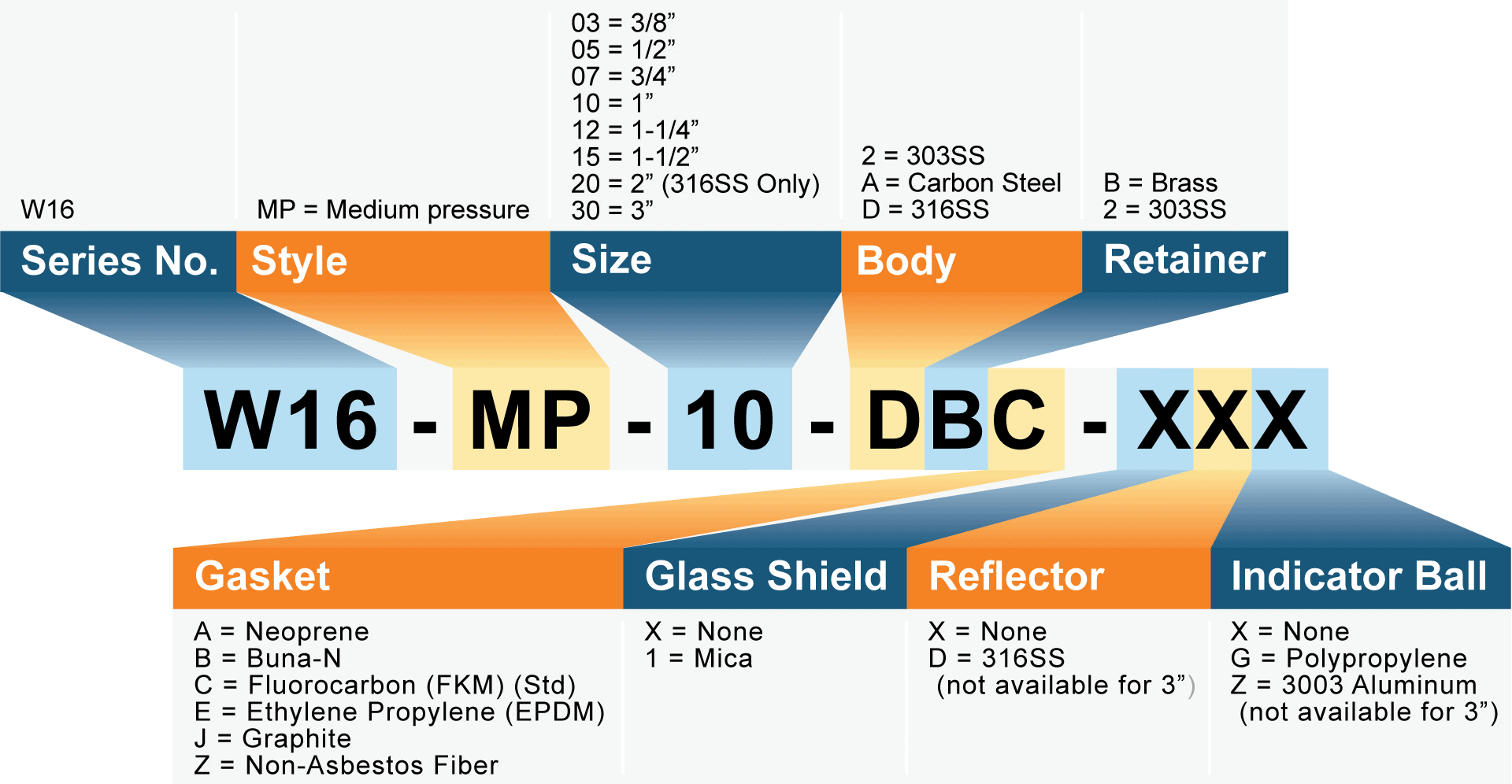

| Style | Connection Size MNPT | Body | Gasket | Glass | Glass Retaining Ring | Cushion |

| LP | 1/4” to 2” | Brass | Fluorocarbon (FKM) | Annealed Borosilicate | Brass | Klingersil® C-4401 |

| MP | 3” | Carbon Steel | Fluorocarbon (FKM) | Annealed Borosilicate | Brass | Klingersil® C-4401 |

| 1/2” to 3” | 316SS | |||||

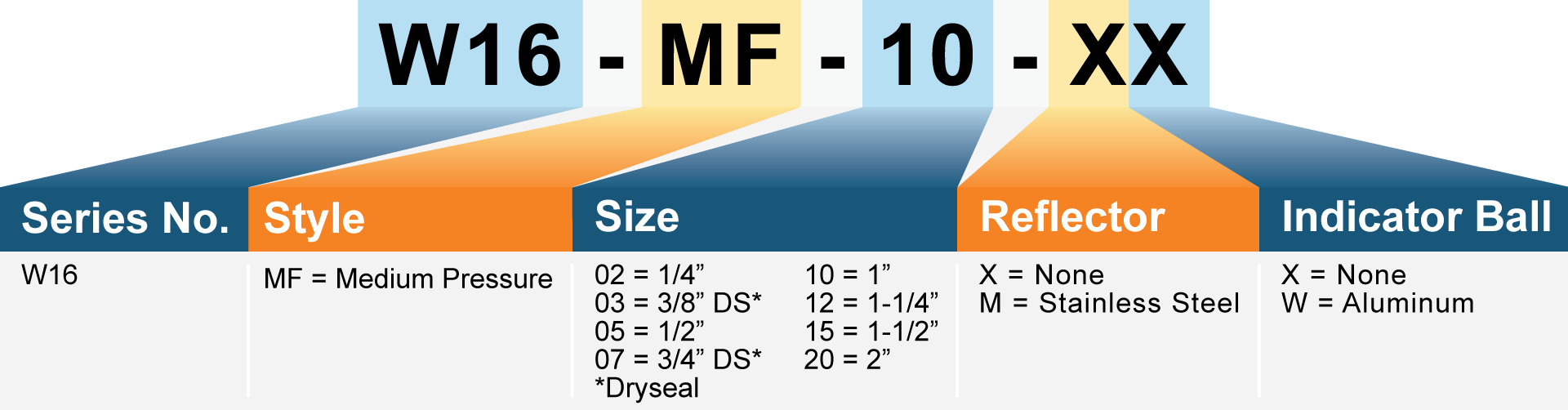

| MF | 1/4” to 2”** | Zinc Plated Steel | - | Fused Soda Lime | - | - |

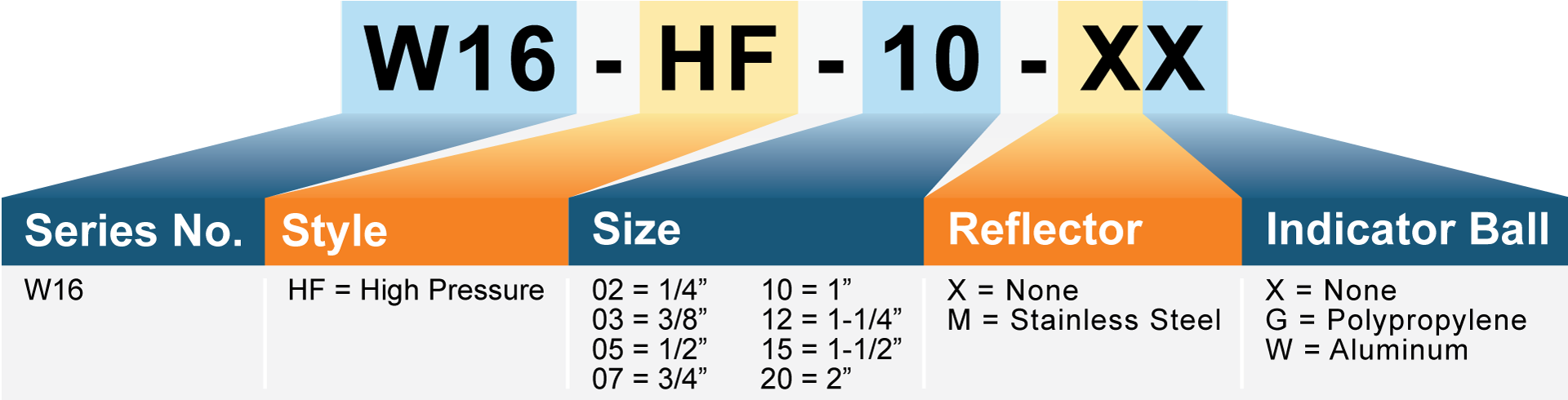

| HF | 1/4” to 2” | Electroless Nickel Plated Steel | - | Fused Soda Lime | - | - |

| SF | 1/4” to 3” | Duplex 2205 SS | - | Fused Borosilicate | - | - |

*Optional materials are available for most sight windows. See matrix or consult factory.

** Style MF 3/8” & 3/4” have MNPTF-Dryseal threads requiring thread sealant

| Standard Non-Steam Ratings | |||||

|---|---|---|---|---|---|

| Size | LP | MP | MF | HF | SF |

| 1/4” | 100 PSIG @ 300°F | - | 125 PSIG @ 250°F | 2000 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 3/8” | 100 PSIG @ 300°F | - | 125 PSIG @ 250°F | 1850 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 1/2” | 90 PSIG @ 300°F | 250 PSIG @ 400°F | 125 PSIG @ 250°F | 1750 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 3/4” | 80 PSIG @ 300°F | 250 PSIG @ 400°F | 125 PSIG @ 250°F | 1500 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 1” | 60 PSIG @ 300°F | 200 PSIG @ 400°F | 125 PSIG @ 250°F | 1250 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 1-1/4” | 35 PSIG @ 300°F | 150 PSIG @ 400°F | 125 PSIG @ 250°F | 1000 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 1-1/2” | 25PSIG @ 300°F | 100 PSIG @ 400°F | 125 PSIG @ 250°F | 750 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 2” | 25 PSIG @ 300°F | 100 PSIG @ 400°F | 125 PSIG @ 250°F | 500 PSIG @ 69°F | 1450 PSIG @ 536°F |

| 3” | - | 150 PSIG @ 400°F | - | - | 362 PSIG @ 536°F |

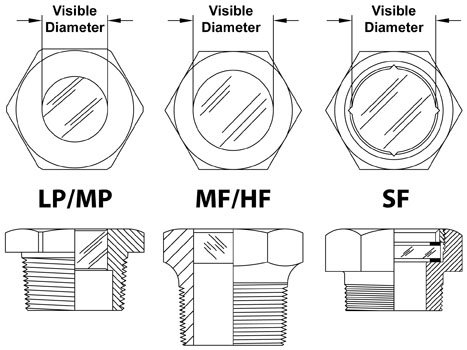

| Visible Diameter | |||||

|---|---|---|---|---|---|

| Size | LP | MP | MF | HF | SF |

| 1/4” | .28” | - | .31” | .31” | .31” |

| 3/8” | .47” | - | .47” | .44” | .39” |

| 1/2” | .59” | .58” | .59” | .56” | .55” |

| 3/4” | .69” | .69” | .78” | .75” | .71” |

| 1” | .93” | .94” | 1.00” | .94” | .87” |

| 1-1/4” | 1.25” | 1.25” | 1.14” | 1.18” | .98” |

| 1-1/2” | 1.53” | 1.50” | 1.53” | 1.43” | 1.18” |

| 2” | 1.53” | 1.23” | 1.97” | 1.88” | 1.46” |

| 3” | - | 2.22” | - | - | 2.17” |

See drawings for more ratings and dimensions.

Application Notes:

- Saturated Steam Service: Contact factory

- Potable Water: Carbon Steel units are not suitable for potable water, but Stainless Steel units are suitable

- Vacuum Service: Style HF and SF only

- Gaseous Service: Style HF and SF only

- Compatibility: Before ordering, verify all materials are compatible with the service media(s), intermittently used cleaners, the environment, and cleaning processes in conjunction with the temperatures and pressures of the application(s) and future applications. John C. Ernst Co. does not make chemical compatibility recommendations. Compatibility is the responsibility of the user and/or specifying party.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov

Replacement Parts

- Please contact our Sales Dept. sales@ernstinstruments.com or call 888-943-5000