SERIES T13

MEDIUM DUTY NON-ASME TUBULAR LEVEL GAUGE VALVES

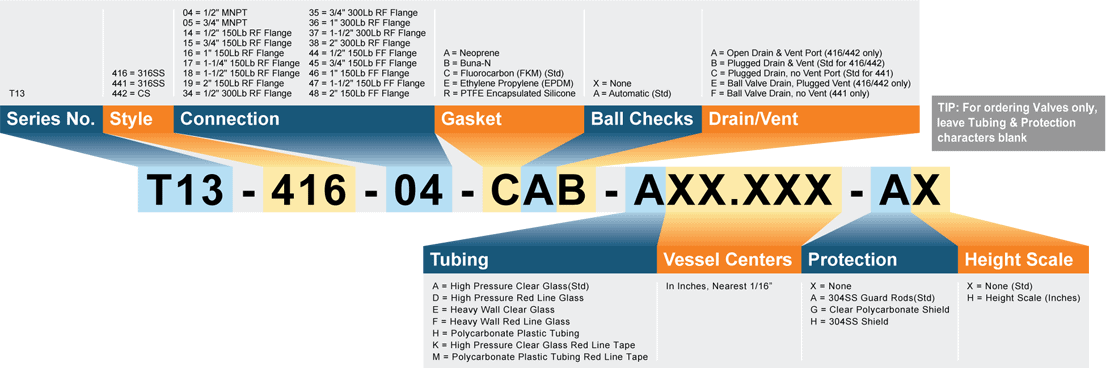

Available as Standard Valves only or contact us for Custom Configured Valves plus Tubing and Protection at customer specified centers

Benefits & Features

- Continuous visual observation of liquid level with no power requirements (power only required for optional sensors)

- Safety Automatic Ball Checks protect against potential process material loss

- Sight Glass Level Gauge Valves sold separately or with glass tubes and protective guard rods or shield

- Suitable for vacuum service (with ball checks removed and with seals other than PTFE)

- Product design allows for at least 3/16” tolerance for specified vessel centers

- Low maintenance

Options

- (4) 3/16” Diameter 304SS Guard Rods to protect glass tube, cut to customer specified centers (Standard recommended for minimum protection of glass tubes)

- (7) different gauge glass or plastic tube types available, cut to customer specified vessel centers

- (5) different gasket materials

- Protective Shield made of 304SS or Polycarbonate (Recommended to protect glass tube and the operator)

- Ball Float kits for easy viewing of water and other medias over 1.0 S.G.

- Proximity Sensors for high/low level detection or alarms

- Metal Height Scale or Height Scale Tape on tube

- 1/2” to 2” 150Lb or 300Lb ASME RF or FF Flange Vessel Connections (Style Size 04)

- 3/4” to 2” 150Lb or 300Lb ASME RF or FF Flange Vessel Connections (Style Size 05)

- Ball Valve Drain

Application Notes:

- Saturated Steam Service: Not suitable

- Potable Water: Only Styles 416 and 441 valves are suitable

- Vacuum Service: Suitable only when automatic ball checks are removed and with any seal other than PTFE or with any tube except FEP tubing (Style 525)

- Compatibility: Before ordering, verify that all the materials of construction, pressures, temperatures, and any other specifications are compatible with the design, media(s), cleaning solutions, and the environment of the application and future applications. Ernst Instruments does not make compatibility recommendations. Compatibility determinations, corrosion or otherwise, are the responsibility of the user and/or specifying party.

WARNING: This product can expose you to certain chemicals, which are known to the State of California to cause cancer or birth defects or other reproductive harm. For more information go to: www.P65Warnings.ca.gov

Parts

- Please contact our sales department for replacement parts.sales@ernstinstruments.com or 888-943-5000